Energy storage behaviors in ferroelectric capacitors fabricated with sub-50 nm poly(vinylidene fluoride) langmuir–blodgett nanofilms

- Select a language for the TTS:

- UK English Female

- UK English Male

- US English Female

- US English Male

- Australian Female

- Australian Male

- Language selected: (auto detect) - EN

Play all audios:

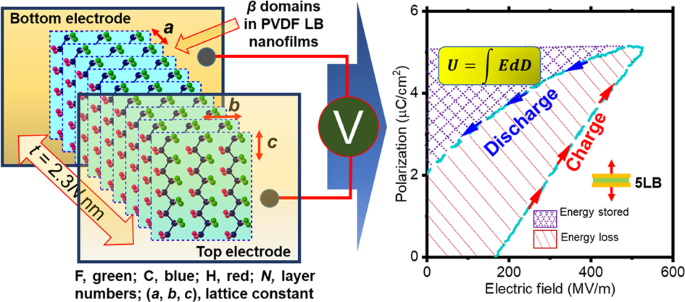

ABSTRACT High-energy storage in polymer dielectrics is limited by two decisive factors: low-electric breakdown strength and high hysteresis under high fields. Poly(vinylidene fluoride)

(PVDF), as a well-known ferroelectric polymer having a high-breakdown strength (700 MV/m) and a high dielectric constant, is suitable for use as a dielectric capacitor film, but

ferroelectric hysteresis from the crystalline phase has prevented its practical application. In our previous study, the ferroelectric switching of crystalline PVDF is suppressed effectively

in PVDF-based Langmuir–Blodgett (LB) nanofilms because of its large interfacial effect, even in an extremely high electric field. This study investigated the ferroelectricity and energy

storage behaviors of PVDF LB nanofilms at sub-50 nm thicknesses. The ferroelectric hysteresis loops were measured using a Sawyer–Tower circuit in different electric fields. An energy density

of 6.0 J/cm3 at 500 MV/m was demonstrated for the 12-nm-thick PVDF LB nanofilm device. You have full access to this article via your institution. Download PDF INTRODUCTION Polymer

dielectrics have attracted much attention because of their low weight, high-breakdown strength, and great reliability and scalability [1]. High-energy density and low-loss dielectrics are

urgently demanded and require a (1) high permittivity, (2) high-electronic breakdown strength (field), (3) low-dissipation factor under low fields, and (4) low hysteresis between 10 Hz and a

few hundred kHz [2]. Polymer dielectrics are therefore promising for next generation energy-storage applications such as wind power and hybrid and electric vehicles [3]. Polar polymers with

permanent dipoles are suitable for use as high-energy storage density dielectrics because of their high permittivity. One such polymer is poly(vinylidene fluoride) (PVDF), with its

distinctively large dielectric constant (_k_~ 10) that is superior to those of other dielectric polymers. Unfortunately, the large dielectric loss in high-_k_ PVDF (tan _δ_~ 0.02) hampers

its application. That loss is 1000 times greater than that of the typical commercial polymer dielectric films (_k_~ 3, tan _δ_~ 0.0002) made from biaxially oriented polypropylene [4].

Suppressing the dielectric hysteresis loss and increasing the energy storage density and charge–discharge efficiency require the manipulation of the PVDF crystallization, including

preferential crystallization and miniaturization of the crystal size [5, 6]. As a semicrystalline polymer, several crystalline forms exist in PVDF materials, including the most common form-I

(_β_) and form-II (_α_). Reportedly, each crystal form has a different potential energy; those of the _β_ and _α_ phases are, respectively, −5.73 and −6.03 kcal/monomer unit [7]. Therefore,

PVDF usually crystallizes into the thermodynamically stable α phase in which the molecular chains take a trans-gauche–trans-gauche (TGTG) conformation and generate a zero net dipole.

Thereby, no corresponding electric polarization is generated [8]. By contrast, under extreme conditions such as high electric field poling, ferroelectric _β_-crystal domains with an

all-trans molecular conformation will be produced, with a bistable intrinsic polarization that can be switched by the application of a reversal electric field. For energy storage

applications, coupling interactions among the PVDF _β_ domains and competition between the polarization and depolarization fields affect the dipole reorientation and energy storage

properties. PVDF materials with a high content of _β_ phase and small _β_-domain size with discontinuous domain boundaries are useful for higher energy storage and low loss because the

domain coupling interactions are weakened to ease the switching back of the aligned dipole in the _β_ domains once the external electric field is removed. To realize that weak coupling

interaction, the reduction of the PVDF film thickness below 100 nm is one effective method, but it is extremely difficult because almost all traditional top-down methods such as mechanical

stretching will lose their function at the sub-100-nm thickness scale [9]. In our earlier work, we proposed a facile bottom-up method to prepare a PVDF quasi-monolayer (~2.3 nm) at the

air–water interface, which can be transferred repeatedly with nanometer-scale precision onto various substrates for multilayered PVDF Langmuir–Blodgett (LB) nanofilms [10]. FT-IR

measurements demonstrated that the _β_-crystal content in the PVDF LB nanofilms reached 95%, one of the highest values ever reported. The total crystallinity was moderate, as high as 50%,

which is comparable to that of bulk PVDF. The PVDF nanofilms provide extraordinary ferroelectricity when used as an insulating layer in electronic devices such as resistive switching

nonvolatile memories and spin valves [6, 11, 12]. These unique PVDF LB nanofilm properties make them possible as high-electric density and low-loss dielectrics because of their well-defined

nanoscale layer structures. Because of the precisely controllable film thickness and the predominance of electroactive _β_ crystals in PVDF LB nanofilms, one can clarify the ferroelectric

behaviors and energy storage properties of sub-50 nm ultrathin films, which is very challenging when using traditional methods. A nonlinear dielectric with a high dielectric constant,

high-electric breakdown strength, and low hysteresis under high fields are required to achieve a high-energy storage density. For this study, we used the Sawyer–Tower method to demonstrate

the ferroelectricity and energy storage properties of ferroelectric capacitors with a sandwich device structure of Al/sub-50-nm-thick PVDF nanofilm/Al. EXPERIMENTAL SECTION MATERIALS PVDF

(_M__n_ = 7.1 × 104, _M__w_/_M__n_ = 2.5; Aldrich Chemical Co. Inc.) was reprecipitated once before use. Amphiphilic poly(_N_-dodecylacrylamide) (pDDA) (_M__n_ = 3.0 × 104, _M__w_/_M__n_ =

3.0) was used as a stabilizer of the PVDF monolayer formation at the water surface. The pDDA was synthesized through free radical polymerization from _N_-dodecylacrylamide initiated by AIBN,

referring to a method described in an earlier report [13]. Solvents including _N_-methyl-2-pyrrolidone (NMP) and chloroform were commercially available. They were used without further

purification for the LB film preparation. Octyltrichlorosilane was purchased from Tokyo Chemical Industry Co. Ltd. for the hydrophobic treatment of the substrate surfaces. Slide glasses were

purchased from Matsunami Glass Ind. Ltd., Japan. Aluminum wire was obtained from the Nilaco Corp., Japan. PREPARATION OF PVDF LB NANOFILMS The LB film preparation was described in our

previous work [10, 14]. Briefly, PVDF and pDDA were dissolved respectively in NMP and chloroform at room temperature with solution concentrations of ca. 1 mM. The two resultant solutions of

pDDA and PVDF were then spread successively onto the water surface to form a stable mixed Langmuir film at a molar mixing ratio of PVDF:pDDA = 50:1 (Fig. 1a). The surface pressure (_π_)–area

(_A_) isotherm was recorded automatically during the compression of the molecules by a PTFE bar. The surface pressure was kept at 30 mN/m for monolayer transfer (Fig. 1b). During the

deposition, the substrate holder was lifted at a dipping speed of 10 mm/min in both upstrokes and downstrokes. The dominant formation of the ferroelectric _β_ crystal (>95%) (an

orthorhombic unit cell with lattice constants of _a_ = 8.45 Å, _b_ = 4.88 Å, and _c_ = 2.55 Å) was also demonstrated. DEVICE FABRICATION The ferroelectric capacitors were fabricated with a

sandwich structure of aluminum (Al)/ PVDF LB nanofilm/aluminum (Al) by the following steps (Fig. 2a). _Step_ 1: Bottom Al bar electrodes as thick as 40 ± 5 nm with a width of 3 mm were

thermally evaporated through a metal mask at a rate of 1.0 Å/s onto clean glass substrates (TSU062H; Balzers, Germany). _Step_ 2: The PVDF monolayers were transferred repeatedly from the

air–water interface onto the Al-coated glass substrates with three layer numbers of 5, 15, and 25, designated as 5LB, 15LB, and 25LB. _Step_ 3: The top electrode was then deposited using a

similar method to that of _Step_ 1, but the metal mask was aligned in an orthogonal orientation. The LB films were protected from burning by liquid nitrogen cooling during the top electrode

Al evaporation. RESULTS AND DISCUSSION SURFACE MORPHOLOGIES OF PVDF LB NANOFILMS ON AN AL ELECTRODE The device fabrication process, which is presented schematically in Fig. 2a, is described

in the experimental section. Aluminum was selected for the top and bottom electrodes because it easily forms a surface oxidation dead layer, causing a depolarization field in ferroelectric

films and hindering a fast polarization reversal and current leakage [15]. We prepared a series of devices with a sandwiched capacitor structure of Al/PVDF LB nanofilm/Al by varying the

number of deposited layers to 5, 15, and 25. The surface morphologies of the Al bottom electrode and PVDF LB nanofilms with different numbers of layers are shown in Fig. 2b–e. The bottom Al

electrode showed a smooth surface with a root mean square surface roughness of 3.7 nm (Fig. 2b). After the PVDF nanosheet deposition, the surface morphologies became rougher, indicating the

successful deposition of the PVDF monolayer from the air–water interface. As shown in AFM images, PVDF nanofibers were formed with the average diameters of 21, 21, and 24 nm, respectively,

for 5LB, 15LB, and 25 LB (Fig. 2c–e). The results further prove that our method controlled the film deposition precisely and that the crystal domain was confined in the nanofibers with

smaller size. It is apparent that the fiber number increased as the deposition cycles increased, which contributed to the overlaying of the nanofibers. Because the average monolayer

thickness was determined as 2.3 nm using a cross-sectional AFM image, as presented in Fig. 2f, the corresponding thicknesses for the different films of 5LB, 15LB, and 25LB were,

respectively, 12, 35, and 58 nm [10]. FERROELECTRIC HYSTERESIS LOOP MEASUREMENTS We used a homemade Sawyer–Tower circuit to evaluate the as-prepared ferroelectric capacitors, with no post

treatment, and assess their ferroelectricity (Fig. 3). The circuit has two capacitors in series, including the reference capacitor (_C__r_) and the ferroelectric capacitor (_C__f_), which

share the charge that passes between them (_Q_). The voltage through the reference capacitor (_V__r_) can be recorded using an oscilloscope. Therefore, the _Q_ value is equal to

_C__r__V__r_, which is useful for calculating the electric polarization value at the ferroelectric capacitor if the electrode area (_A_) is known (Eqn. 1). In this study, a triangle waveform

voltage with a frequency of 10 Hz was applied to the reference capacitor with a capacitance value of 1 μF. The voltage magnitude was changed gradually for the different samples. $$D =

\frac{{C_rV_r}}{A}$$ (1) Dielectric materials are electric insulators through which no electric charge can pass freely. Instead, dielectric polarization is induced by an applied electric

field, resulting in the accumulation of positive charges on one side and negative charges on the opposite side. These accumulated charges enable electric charge storage [16]. The polymer

dielectrics include linear and nonlinear types, which respectively demonstrate linear and nonlinear electric displacement (_D_) responses to an applied effective electric field (_E_),

obtained by considering the induced voltage across the reference capacitor from the applied electric field. Considering the easy oxidation of the aluminum electrodes, especially the bottom

electrode, the depolarization electric field is another important factor that influences the final hysteresis loops. Figure 4a–c shows the final electric displacement (_D_)-electric field

(_E_) hysteresis loops that results after considering the effects of both the induced voltage across the reference capacitor and the depolarization electric field from the interfacial oxide

layer [6]. The calculation details are depicted in the supplementary information. Under a low electric field, the dielectric behavior was demonstrated to be that of a linear-type dielectric

because the electric field was sufficient to polarize mobile amorphous dipoles but was not sufficiently strong to polarize the crystalline dipoles in the PVDF LB nanofilms [16]. Therefore,

at the discharge stage, the polarized dipole easily reverted to its original state, following its charge curve. Under stronger electric fields, the dipole orientation in the crystalline

domains can be aligned along the electric field. However, the discharge process could not revert all the polarized crystals back to their original states, thereby giving rise to nonlinear

_D_–_E_ hysteresis loops and remanent polarizations (a polarization value at a zero electric field, Fig. 4a). However, as the film thickness increased, the hysteresis loop gradually grew to

a more saturated shape because the effect of the depolarization field originating from the interfacial Al2O3 layer on the ferroelectric polarization became weaker. The remanent (_P__r_) and

spontaneous (_P__s_) polarization values are presented in Fig. 4d. It is readily apparent that both the _P__r_ and _P__s_ values increase with the electric field magnitude until the electric

field reaches its maximum electrical strength. The nonsaturated behavior can also be interpreted in terms of the interfacial depolarization field and the limited crystallinity (50%) [10,

17]. The asymmetric hysteresis loops of the 5LB films (4 and 5 V, Fig. 4a) also imply that interfacial effects become more prominent as the film thickness decreases [18]. ENERGY STORAGE

BEHAVIORS To characterize the energy storage properties of dielectrics, _D_–_E_ loops are commonly used. For linear dielectrics, the charge curves always follow the discharge curves, as

there is no hysteresis loss. The stored energy density can be released effectively, as shown in Eqn. 2, where _ε__r_ and _ε__0_ respectively denote the relative dielectric constant and the

vacuum permittivity. However, the discharge curve in nonlinear dielectrics (ferroelectrics) does not follow the charge curve because the remanent polarization generates unreleased energy,

which is the energy loss (Fig. 5a). The energy stored (_U__nl_) and energy loss (_U__loss_) are marked clearly. In this case, the stored energy density is expressed as Eqn. 3, and the

charge–discharge efficiency (_η_) in nonlinear dielectrics is expressed as Eqn. 4. According to these equations, a nonlinear dielectric with a high dielectric constant, high-electric

breakdown strength, and low hysteresis under high fields are required to achieve a high-energy storage density. The dielectric constant and breakdown strength of PVDF are reportedly as high

as 10–12 and 700 MV/m, respectively, for bulky materials at room temperature [5]. $${\it{U}}_{\it{l}} = \mathop {\scriptstyle\int }\nolimits {\it{EdD}} = 0.5{\it{\varepsilon \varepsilon

}}_{\mathrm{0}}{\it{E}}^2$$ (2) $${\it{U}}_{{\it{nl}}} = \mathop {\scriptstyle\int }\nolimits {\it{EdD}} \, \ne \, 0.5\varepsilon \left( {\it{E}} \right)\varepsilon _0{\it{E}}^2$$ (3)

$${\it{\eta = }}\frac{{{\it{U_{nl}}}}}{{{\it{U_{nl} + U_{loss}}}}}$$ (4) In these equations, _E_, _D_, _ε_, and _ε_0, respectively, represent the electric field, electric displacement,

dielectric constant, and permittivity. The details of the energy storage behaviors were investigated for these ferroelectric capacitors. We show the stored energy as a function of the

electric field for each sample (Fig. 5b). These results show the distinct possibility of achieving a high-energy storage density in our devices. All the devices exhibited similar trends: the

energy density stored increased as the electric field increased. The highest energy stored was 6.0 J/cm3 (5LB) at 500 MV/m, which is comparable to those of most polymer-based dielectrics

[16, 19, 20]. On the other hand, the energy loss invariably increased as the electric field and the film thickness increased because of the increased remanent polarization (Fig. 5c). The

small _β_-crystal size is beneficial for the suppression of hysteresis-induced dielectric loss because the ferroelectric domain coupling can be “nanoconfined” at discontinuous boundaries, in

which the polarized domain readily switches back to its original state once removed from the external electric field. The fewer PVDF nanofibers in the thinner film (5LB) provide more

limited space for the growth of the _β_-crystal domains under the external electric field than in the thicker films. However, the domain coupling interactions might be hindered by the

surrounding pDDA materials, which can explain the easy dipole reorientation. Therefore, the thinner films gave rise to a lower remanent polarization and a lower dielectric loss. The

charge–discharge efficiency (_η_) of the devices is presented in Fig. 5d. It is noteworthy that the 5LB devices proved to have the highest efficiency over the thicker devices because of

their slim hysteresis. The efficiency value for 25LB decreases from 90% to 20% as the electric field increases, which might be ascribed to the greater energy loss induced by the

ferroelectric hysteresis with higher remanent polarization and the current leakage from the breakdown of the pDDA component, which was observed as the electric breakdown strength of 270 MV/m

[21]. These results suggest that the nano-confinement-induced miniaturization of the PVDF crystal size can enhance energy storage behaviors in ferroelectric dielectrics. We also confirmed

the D–E curves of pDDA using the same Sawyer–Tower circuit. There was no output response observed. During the film preparation, only a tiny amount of pDDA was used, with a molar ratio of

PVDF:pDDA = 50:1. The main function of the pDDA is to stabilize the monolayer formation of PVDF at the air–water interface. Therefore, the pDDA may have little effect on the final energy

storage. It is expected to be instructive, in future studies, to develop PVDF monolayers by mixing inorganic nanomaterials and dielectric polymers with a high-electric strength [3].

CONCLUSIONS In summary, PVDF LB nanofilms with thicknesses of less than 60 nm were studied for use in ferroelectric energy storage capacitors. PVDF LB nanofilms have a unique layer structure

consisting of amorphous PVDF and nanofiber-structured (crystalline) PVDF components surrounded by amphiphilic pDDA, which is suitable for high-energy density and low-loss dielectric

investigations. A series of ferroelectric hysteresis loops were obtained for devices in different electric fields. The highest energy stored was 6.0 J/cm3 for a film with a thickness of 12

nm, with a charge–discharge efficiency of 34.8%. This was the first report that depicts the energy storage behavior of ferroelectric devices at such a thickness scale. Though surface effects

such as the local depolarization field, surface roughness, and crystallinity should be clarified in detail [18], an even higher energy storage density can be achieved for our devices after

device optimization. REFERENCES * Li Q, Chen L, Gadinski MR, Zhang S, Zhang G, Li HU, et al. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature.

2015;523:576–9. Article CAS Google Scholar * Mackey M, Schuele DE, Zhu L, Flandin L, Wolak MA, Shirk JS, et al. Reduction of dielectric hysteresis in multilayered films via

nanoconfinement. Macromolecules. 2012;45:1954–62. Article CAS Google Scholar * Prateek Thakur VK, Gupta RK. Recent progress on ferroelectric polymer-based nanocomposites for high energy

density capacitors: synthesis, dielectric properties, and future aspects. Chem Rev. 2016;116:4260–317. Article Google Scholar * Baer E, Zhu L. 50th anniversary perspective: dielectric

phenomena in polymers and multilayered dielectric films. Macromolecules. 2017;50:2239–56. Article CAS Google Scholar * Guan F, Wang J, Pan J, Wang Q, Zhu L. Effects of polymorphism and

crystallite size on dipole reorientation in poly(vinylidene fluoride) and its random copolymers. Macromolecules. 2010;43:6739–48. Article CAS Google Scholar * Zhu H, Yamamoto S, Matsui J,

Miyashita T, Mitsuishi M. Ferroelectricity of poly(vinylidene fluoride) homopolymer Langmuir–Blodgett nanofilms. J Mater Chem C. 2014;2:6727–31. Article CAS Google Scholar * Hasegawa R,

Kobayashi M, Tadokoro H. Molecular conformation and packing of poly(vinylidene fluoride). Stability of three crystalline forms and the effect of high pressure. Polym J. 1972;3:591–9. Article

CAS Google Scholar * Furukawa T. Ferroelectric properties of vinylidene fluoride copolymers. Phase Transit. 1989;18:143–211. Article CAS Google Scholar * Nasir M, Matsumoto H,

Minagawa M, Tanioka A, Danno T, Horibe H. Formation of β-phase crystalline structure of PVDF nanofiber by electrospray deposition: additive effect of ionic fluorinated surfactant. Polym J.

2007;39:670–4. Article CAS Google Scholar * Zhu H, Mitsuishi M, Miyashita T. Facile preparation of highly oriented poly(vinylidene fluoride) Langmuir–Blodgett nanofilms assisted by

amphiphilic polymer nanosheets. Macromolecules. 2012;45:9076–84. Article CAS Google Scholar * Zhu H, Yamamoto S, Matsui J, Miyashita T, Mitsuishi M. Resistive non-volatile memories

fabricated with poly(vinylidene fluoride)/poly(thiophene) blend nanosheets. RSC Adv. 2018;8:7963–8. Article CAS Google Scholar * Zhang X, Tong J, Zhu H, Wang Z, Zhou L, Wang S, et al.

Room temperature magnetoresistance effects in ferroelectric poly(vinylidene fluoride) spin valves. J Mater Chem C. 2017;5:5055–62. Article CAS Google Scholar * Miyashita T, Mizuta Y,

Matsuda M. Studies on Langmuir–Blodgett multilayer formation from preformed poly(_N_-alkylacrylamides). Br Polym J. 1990;22:327–31. Article CAS Google Scholar * Zhu H, Matsui J, Yamamoto

S, Miyashita T, Mitsuishi M. Solvent-dependent properties of poly(vinylidene fluoride) monolayers at the air–water interface. Soft Matter. 2015;11:1962–72. Article CAS Google Scholar *

Nakajima T, Abe R, Takahashi Y, Furukawa T. Intrinsic switching characteristics of ferroelectric ultrathin vinylidene fluoride/trifluoroethylene copolymer films revealed using Au electrode.

Jpn J Appl Phys. 2005;44:L1385. Article CAS Google Scholar * Zhu L, Wang Q. Novel ferroelectric polymers for high energy density and low loss dielectrics. Macromolecules. 2012;45:2937–54.

Article CAS Google Scholar * Zhou Y, Chan HK, Lam CH, Shin FG. Mechanisms of imprint effect on ferroelectric thin films. J Appl Phys. 2005;98:024111. Article Google Scholar * Nakajima

T, Takahashi Y, Okamura S, Furukawa T. Nanosecond switching characteristics of ferroelectric ultrathin vinylidene fluoride/trifluoroethylene copolymer films under extremely high electric

field. Jpn J Appl Phys. 2009;48:09KE04. Google Scholar * Chu B, Zhou X, Ren K, Neese B, Lin M, Wang Q, et al. A dielectric polymer with high electric energy density and fast discharge

speed. Science. 2006;313:334–6. Article CAS Google Scholar * Xie Y, Jiang W, Fu T, Liu J, Zhang Z, Wang S. Achieving high energy density and low loss in PVDF/BST nanodielectrics with

enhanced structural homogeneity. ACS Appl Mater Interfaces. 2018;10:29038–47. Article CAS Google Scholar * Budianto Y, Aoki A, Miyashita T. Ultrathin polymer film capacitor composed of

poly(_N_-alkylacrylamide) Langmuir–Blodgett films. Macromolecules. 2003;36:8761–5. Article CAS Google Scholar Download references ACKNOWLEDGMENTS The work was partially supported by

Grants-in-Aid for Young Scientists (B) (16K17953) and Scientific Research (B) (16H04197) from the Japan Society for the Promotion of Science (JSPS). The work was also supported by the

Cooperative Research Program “Network Joint Research Center for Materials and Devices”: Dynamic Alliance for Open Innovation Bridging Human, Environment and Materials (MEXT), the

Morinomiyako Project for Empowering Women in Research, the Tohoku University Center for Gender Equality Promotion (TUMUG), and the TAGEN project, Tohoku University. MM thanks the Nohmura

Foundation for Membrane Structure’s Technology for financial support. AUTHOR INFORMATION AUTHORS AND AFFILIATIONS * Institute of Multidisciplinary Research for Advanced Materials, Tohoku

University, 2-1-1 Katahira, Aoba-ku, Sendai, 980-8577, Japan Huie Zhu, Tokuji Miyashita & Masaya Mitsuishi Authors * Huie Zhu View author publications You can also search for this author

inPubMed Google Scholar * Tokuji Miyashita View author publications You can also search for this author inPubMed Google Scholar * Masaya Mitsuishi View author publications You can also

search for this author inPubMed Google Scholar CORRESPONDING AUTHORS Correspondence to Huie Zhu or Masaya Mitsuishi. ETHICS DECLARATIONS CONFLICT OF INTEREST The authors declare that they

have no conflict of interest. ADDITIONAL INFORMATION PUBLISHER’S NOTE: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

SUPPLEMENTARY INFORMATION SUPPLEMENTARY INFORMATION RIGHTS AND PERMISSIONS Reprints and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Zhu, H., Miyashita, T. & Mitsuishi, M. Energy

storage behaviors in ferroelectric capacitors fabricated with sub-50 nm poly(vinylidene fluoride) Langmuir–Blodgett nanofilms. _Polym J_ 51, 795–801 (2019).

https://doi.org/10.1038/s41428-019-0194-3 Download citation * Received: 23 November 2018 * Revised: 25 March 2019 * Accepted: 26 March 2019 * Published: 23 April 2019 * Issue Date: August

2019 * DOI: https://doi.org/10.1038/s41428-019-0194-3 SHARE THIS ARTICLE Anyone you share the following link with will be able to read this content: Get shareable link Sorry, a shareable

link is not currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt content-sharing initiative