Laser slice thinning of gan-on-gan high electron mobility transistors

- Select a language for the TTS:

- UK English Female

- UK English Male

- US English Female

- US English Male

- Australian Female

- Australian Male

- Language selected: (auto detect) - EN

Play all audios:

ABSTRACT As a newly developed technique to slice GaN substrates, which are currently very expensive, with less loss, we previously reported a laser slicing technique in this journal. In the

previous report, from the perspective of GaN substrate processing, we could only show that the GaN substrate could be sliced by a laser and that the sliced GaN substrate could be reused. In

this study, we newly investigated the applicability of this method as a device fabrication process. We demonstrated the thinning of GaN-on-GaN high-electron-mobility transistors (HEMTs)

using a laser slicing technique. Even when the HEMTs were thinned by laser slicing to a thickness of 50 μm after completing the fabrication process, no significant fracture was observed in

these devices, and no adverse effects of laser-induced damage were observed on electrical characteristics. This means that the laser slicing process can be applied even after device

fabrication. It can also be used as a completely new semiconductor process for fabricating thin devices with thicknesses on the order of 10 μm, while significantly reducing the consumption

of GaN substrates. SIMILAR CONTENT BEING VIEWED BY OTHERS SMART-CUT-LIKE LASER SLICING OF GAN SUBSTRATE USING ITS OWN NITROGEN Article Open access 09 September 2021 ELIMINATION OF THE

INTERNAL ELECTROSTATIC FIELD IN TWO-DIMENSIONAL GAN-BASED SEMICONDUCTORS Article Open access 28 August 2020 VAN DER WAALS INTEGRATION OF GAN LIGHT-EMITTING DIODE ARRAYS ON FOREIGN GRAPHENE

FILMS USING SEMICONDUCTOR/GRAPHENE HETEROSTRUCTURES Article Open access 08 July 2022 INTRODUCTION Gallium nitride (GaN) is a widebandgap semiconductor material and has especially many

applications, among which light-emitting diodes (LED) and high-electron-mobility transistors (HEMTs) are already in practical use. GaN is also known to be a suitable material for power

devices owing to its high critical electric field strength and high electron saturation velocity. Since heteroepitaxial GaN is available, it can be grown on Si, SiC, Al2O3, and other

materials; however, the quality of crystals grown on GaN substrates is the highest, with the fewest crystal defects. It is expected that the use of high-quality crystals will lead to the

higher yield and reliability of devices fabricated on GaN layers; therefore, the research and development of GaN devices on GaN substrates is also being actively pursued especially in the

fields of next-generation power devices1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19 and high-power amplification of radio frequencies for the fifth-generation and beyond wireless

communication20,21,22,23,24,25,26,27,28,29,30,31,32. However, owing to the high price of GaN substrates, GaN-based devices fabricated on GaN substrates have not yet been commercialized in a

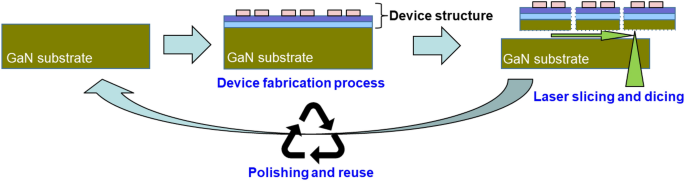

wide range of fields. To address this problem, we have developed a laser-based method of slicing GaN substrates33,34. This method not only suppresses kerf loss during the slicing of GaN

substrates from GaN bulk crystals, but also minimizes the consumption of expensive GaN substrates if it can be used in processes such as that shown in Fig. 1. Since we have already confirmed

that the laser-sliced substrate side can be reused after polishing, as reported in reference33, if the device can operate properly after this slicing, the amount of the GaN substrate

consumed will only be the thickness of the sliced device layer and that removed by polishing for reuse. For example, as similarly indicated in reference33, if we remove a portion with a

thickness of 50 µm as a device layer by laser slicing and remove another potion with a thickness of 50 µm by polishing to reuse the GaN substrate, we can obtain one device layer per

100-µm-thick GaN substrate, whereas previously, one device layer could only be obtained per 400-µm-thick GaN substrate. In addition, the thinner the device, the better the heat dissipation,

making it desirable to reduce the thickness of the substrate under the device. The process shown in Fig. 1 is also convenient for obtaining thin devices. This laser slicing process reported

here is similar to the Smart Cut™ technology35,36,37,38,39, if we look for something similar among conventional methods. Compared with the conventional Smart Cut™ technology, it is difficult

to use this new laser slicing method to cut out a very thin GaN layer of submicron thickness because GaN is decomposed during laserslicing33. However, in our laser slicing method, the

slicing plane can be formed by a laser, not by ion implantation. This allows processing at any position in the substrate. This means that we can peel off the device layer by irradiating

laser from the backside surface after fabricating the device. Since laser slicing can be performed after device fabrication, it is possible for substrates to pass through the fabrication

process as a single crystal. With this laser slicing, there is no need to develop methods of bonding to another substrate or to consider the chemical and thermal effects on the bonding

interface during device fabrication. In this study, we investigated whether the process shown in Fig. 1 is possible, i.e., whether the device can be sliced after the fabrication process,

and, if so, whether the device will work properly after slicing. In this study, we focused on HEMTs as the devices to be thinned by laser slicing. EXPERIMENTS An Al0.2Ga0.8 N/GaN (20/900 nm)

heterostructure was grown by metal organic vapor phase epitaxy (MOVPE) on a commercially available semi-insulating (SI) GaN substrate. Ohmic contacts were formed by evaporating Mo/Al/Mo/Au,

followed by annealing at 850 °C in N2 ambient. As a field-plate dielectric, SiN was deposited by plasma-enhanced chemical vapor deposition. To electrically isolate each device, B+ ions were

implanted. Various HEMTs were fabricated with different structural parameters; typically, the gate-to-source spacing, gate length, gate-to-drain spacing, and gate width were 2, 2, 5, and

100 µm, respectively. As electrode pads of the source, drain, and gate, Ni/Au with a size of 90 µm × 90 µm square was deposited. After measuring the electrical characteristics of on-wafer

HEMT devices, dicing lines at intervals of 5 mm on the 50-µm-thick part of the device side were formed by the Stealth Dicing™ process40, and a slice plane was formed at a depth of 50 µm from

the device side with a laser slicing technique. In both laser processes, the laser was irradiated from the back side surface of the sample, as shown in Fig. 1. The laser used for slicing in

this study was a sub-nanosecond 532 nm green laser with a peak power density of 2.5 × 1011 W/cm2 and a beam diameter of 1 µm. To maintain the beam diameter even at a depth of 350 µm in GaN,

this laser was equipped with a spatial light modulator (LCOS-SLM, Hamamatsu Photonics) to compensate for spherical aberration. The details of laser slicing conditions and procedure are

described in reference33. Then, the electrical characteristics of thin-chip HEMT devices are measured again to evaluate the effects of laser slicing on the characteristics. RESULTS AND

DISCUSSION Figure 2 shows photographs of a sample before and after laser slicing. Figure 2a shows HEMT devices immediately after their fabrication on the SI-GaN substrate. Figure 2b shows

nine sample chips with a thickness of 50 µm and a size of 5 mm square obtained by the Stealth Dicing™ process and laser slicing. Figure 2c shows the remaining 350-µm-thick, 1.5-cm-square

SI-GaN substrate. The transparent area in Fig. 2b appears dark grey, and the surface of the GaN substrate in Fig. 2c appears silver, because Ga precipitated owing to the decomposition of GaN

during laser slicing. In Fig. 2c, we can see grid like stripes at intervals of 5 mm, which are attached to the precipitated Ga and can be removed by appropriate cleaning. As shown in

reference33, this part of the substrate can be reused as a substrate for epitaxial growth after polishing, indicating that the device fabrication process shown in Fig. 1 is possible. Figure

3 shows IDS–VDS and IDS–VGS curves of a HEMT device with a source–drain distance of 9 µm, a gate width of 100 µm, and a source–gate distance of 2 µm in the on-wafer state and after thinning

by laser slicing. It can still be operated as a HEMT device even after laser slicing. There were insignificant changes in electrical characteristics before and after slicing, with only a

slight decrease in IDS in the HEMT device after slicing. As shown in Fig. 3b, the on-resistance appears to increase from 12.9 Ωmm (on-wafer) to 13.8 Ωmm (as-sliced) with fully opened gate

(VGS = 10 V). As reported in reference33, the depth of damage caused by laser slicing is around 40 µm from the sliced surface. The HEMT structures in this study are 50 µm away from the

sliced surface; thus, significant damage in the form of cracks or alteration of GaN should not reach the devices. Therefore, we considered that the changes in electrical characteristics

might be due to the deformation of the GaN chip caused by thinning. Figure 4 shows the height distribution of a HEMT sample surface measured using a laser height meter. As shown in Fig. 4,

the sample is warped in a downward convex direction. This warpage is considered to be caused by the following factors, which appear as a change in shape caused by the thinning. The

compressive stress on the device side of the GaN chip is caused by metal cooling and shrinking after deposition, the film stress of SiN deposited as a protective film, and the AlGaN layer.

The tensile stress on the back surface of the GaN chip is caused by the Twyman effect41,42 with the rough as-sliced back surface. All of these caused the warping of the chip in a downward

convex direction. On the other hand, the only thing that warped the chip in an upward convex direction is the tensile stress on the device side of the GaN chip due to the expansion of the

surface side caused by boron ion implantation for electrical isolation. It is difficult to quantitively compare the effects of these factors, but the results show that the compressive stress

on the surface side seems to be large and the warp is in a downward convex direction. As discussed in references43,44,45,46, the warping occurs in the direction in which the strain relaxes

at the AlGaN/GaN interface and the electron density in two-dimensional electron gas (2DEG) decreases, which results in an increase in the resistance of the HEMT device and a decrease in IDS.

To determine whether chip warpage affect the resistance, we measured the I–V characteristics of a 50-µm-wide, 500-µm-long 2DEG channel of various shapes, which was also on a laser-sliced

chip. The resistance component of this device is mostly accounted for by 2DEG channel resistance; therefore, the resistance of this device is more sensitive to a change in 2DEG channel

resistance than to the change in the resistance of the measured HEMT device. Figure 5 shows the I–V characteristics for each shape. As shown in Fig. 5, the resistance increased after laser

slicing from 247 Ωmm (on-wafer) to 304 Ωmm; however, the resistance returned to almost the same value (254 Ωmm) as that under the on-wafer condition when the sliced chip was flattened. This

means that the changes in electrical characteristics before and after laser slicing were almost entirely due to the warping of the sample and no significant irreversible changes in

electrostatic properties occurred. The change in shape can be corrected by attaching the chip to a heat spreader with sufficient composition. CONCLUSION We demonstrated the thinning of

GaN-on-GaN HEMTs to 50 µm thickness by laser slicing. We also confirmed that GaN-on-GaN HEMTs remained operational even after laser slicing and there were no significant changes in the

electrostatic properties of the HEMTs after slicing, except for the warping induced by the thinning. This means that the laser slicing process can be applied even after device fabrication.

It can also be used as a semiconductor process for fabricating thin devices with thicknesses on the order of 10 µm without polishing the GaN substrate. CHANGE HISTORY * _ 17 MAY 2022 A

Correction to this paper has been published: https://doi.org/10.1038/s41598-022-12628-0 _ REFERENCES * Amano, H. _et al._ The 2018 GaN power electronics roadmap. _J. Phys. D Appl. Phys._ 51,

163001 (2018). Article ADS Google Scholar * Dang, G. T. _et al._ High voltage GaN Schottky rectifiers. _IEEE Trans. Electron Devices_ 47, 692 (2000). Article ADS CAS Google Scholar *

Yoshizumi, Y., Hashimoto, S., Tanabe, T. & Kiyama, M. High-breakdown-voltage pn-junction diodes on GaN substrates. _J. Cryst. Growth_ 298, 875 (2007). Article ADS CAS Google Scholar

* Matocha, K., Chow, T. P. & Gutmann, R. J. High-voltage normally off GaN MOSFETs on sapphire substrates. _IEEE Trans. Electron Devices_ 52, 6 (2005). Article ADS CAS Google Scholar

* Suda, J. _et al._ Nearly ideal current-voltage characteristics of schottky barrier diodes formed on hydride-vapor-phase-epitaxy-grown GaN free-standing substrates. _Appl. Phys. Express_

3, 101003 (2010). Article ADS Google Scholar * Hu, Z. _et al._ Near unity ideality factor and Shockley-Read-Hall lifetime in GaN-on-GaN p-n diodes with avalanche breakdown. _Appl. Phys.

Lett._ 107, 243501 (2015). Article ADS Google Scholar * Qi, M. _et al._ High breakdown single-crystal GaN p-n diodes by molecular beam epitaxy. _Appl. Phys. Lett._ 107, 2301 (2015).

Article Google Scholar * Oikawa, T., Saijo, Y., Kato, S., Mishima, T. & Nakamura, T. Formation of definite GaN p-n junction by Mg-ion implantation to n–GaN epitaxial layers grown on a

high-quality free-standing GaN substrate. _Nucl. Instrum. Methods Phys. Res. A._ 365, 168 (2015). Article CAS Google Scholar * Nie, H., Diduck, Q., Alvarez, B., Edwards, A. P., Kayes, B.

M., Zhang, M., Ye, G., Prunty, T., Bour, D., & Kizilyalli, I. C.1.5-kV and 2.2-m\(\Omega \)-cm2 Vertical GaN transistors on Bulk-GaN Substrates. _IEEE Electron Device Lett._ 35, 939

(2014). * Oka, T., Ina, T., Ueno, Y., & Nishii, J. 1.8m\(\Omega \)-cm2 vertical GaN-based trench metal-oxide-semiconductor field-effect transistors on a free-standing GaN substrate for

1.2-kV-class operation0. _Appl. Phys. Express_ 8, 054101 (2015). * Shibata, D., Kajitani, R., Ogawa, M., Tanaka, K., Tamura, S., Hatsuda, T., Ishida, M., & Ueda, T. 1.7 kV/ 1.0 m\(\Omega

\)cm2 Normally-off Vertical GaN Transistor on GaN substrate with Regrown p-GaN/AlGaN/GaN Semipolar Gate Structure, _IEEE IEDM Tech. Gid._ 10.1 (2016). * Meneghini, M. _et al._ Reliability

and failure analysis in power GaN-HEMTs; An overview. _IEEE IRPS_ 1, 3B-2.1-3B–2.8 (2017). Google Scholar * Tanaka, A. _et al._ Facet dependence of leakage current and carrier concentration

in m-plane GaN Schottky barrier diode fabricated with MOVPE. _Phys. Status Solidi A_ 214, 1600829 (2017). Article ADS Google Scholar * Barry, O. I. _et al._ Effect of V/III ratio on the

surface morphology and electrical properties of m-plane (10–10) GaN homoepitaxial layers. _J. Cryst. Growth_ 468, 552 (2017). Article ADS CAS Google Scholar * Zhang, Y. _et al._ 1200 V

GaN vertical fin power field-effect transistors. _IEEE IEDM Tech. Dig._ 9(2), 1 (2017). Google Scholar * Fukushima, H. _et al._ Vertical GaN p-n diode with deeply etched mesa and the

capability of avalanche breakdown. _Appl. Phys. Express_ 12, 026502 (2019). Article ADS Google Scholar * Yoshino, M. _et al._ Fully ion implanted normally-off GaN DMOSFETs with ALD-Al2O3

gate dielectrics. _Materials_ 12, 689 (2019). Article ADS CAS Google Scholar * Yoshida, T. & Shibata, M. GaN substrates having a low dislocation density and a small off-angle

variation prepared by hydride vapor phase epitaxy and maskless-3D. _Jpn. J. Appl. Phys._ 59, 07107 (2020). Article Google Scholar * Kawasaki, S. _et al._ Experimental demonstration of GaN

IMPATT diode at X-band. _Appl. Phys. Lett._ 14, 046501 (2021). CAS Google Scholar * Asif Khan, M. & Yang, J. W. GaN-AlGaN heterostructure field-effect transistors over bulk GaN

substrates. _Appl. Phys. Lett._ 76, 3807 (2000). Article ADS CAS Google Scholar * Chu, K. K. _et al._ 9.4-W/mm power density AlGaN-GaN HEMTs on free-standing GaN substrates. _IEEE

Electron. Device Lett._ 25, 596 (2004). Article ADS CAS Google Scholar * Irokawa, Y. _et al._ DC characteristics of AlGaN/GaN heterostructure field-effect transistors on freestanding GaN

substrates. _Electrochem. Solid-State Lett._ 7, G8 (2004). Article CAS Google Scholar * Chu, K. K., Chao, P. C. & Windyka, J. A. Stable high power GaN-on-GaN HEMT. _Int. J. High

Speed Electron. Syst._ 14, 738 (2004). Article CAS Google Scholar * Leach, J. H. _et al._ Carrier velocity in InAlN/AlN/GaN heterostructure field effect transistors on Fe-doped bulk GaN

substrates. _Appl. Phys. Lett._ 96, 102109 (2010). Article ADS Google Scholar * Oshimura, Y. _et al._ AlGaN/GaN heterostructure field-effect transistors on Fe-doped GaN substrates with

high breakdown voltage. _Jpn. J. Appl. Phys._ 50, 084102 (2011). Article ADS Google Scholar * Tapajna, M. _et al._ Non-arrhenius degradation of AlGaN/GaN HEMTs grown on bulk GaN

substrates. _IEEE Electron Device Lett._ 33, 1126 (2012). Article ADS CAS Google Scholar * Kruszewski, P. _et al._ AlGaN/GaN HEMT structures on ammono bulk GaN substrate. _Semicond. Sci.

Technol._ 29, 075004 (2014). Article ADS CAS Google Scholar * Anderson, T. J. _et al._ Effect of reduced extended defect density in MOCVD grown AlGaN/GaN HEMTs on native GaN substrates.

_IEEE Electron Device Lett._ 37, 28 (2016). Article ADS CAS Google Scholar * Alshahed, M., Alomari, M., Harendt, C., Burghartz, J. N., Wächter, C., Bergunde, T., Lutgen, S. 600V,

low-leakage AlGaN/GaN MIS-HEMT on bulk GaN substrates. In _46_th_ European Solid-State Device Research Conference_ 202 (2016). * Heuken, L. _et al._ Temperature dependent vertical conduction

of GaN HEMT structures on Silicon and bulk GaN substrates. _Phys. Status Solidi A_ 216, 1800482 (2019). Google Scholar * Chu, J. _et al._ Abnormal increase of 2DEG density in AlGaN/GaN

HEMT grown on free-standing GaN substrate. _Jpn. J. Appl. Phys._ 60, 035506 (2021). Article ADS CAS Google Scholar * Ma, Q., Ando, Y. & Wakejima, A. Dynamic characteristics after

bias stress of GaN HEMTs with field plate on free-standing GaN substrate. _Electron. Lett._ 57, 591 (2021). Article ADS CAS Google Scholar * Tanaka, A. _et al._ Smart-cut-like laser

slicing of GaN substrate using its own nitrogen. _Sci. Rep._ 11, 17949 (2021). Article ADS CAS Google Scholar * Sena, H. _et al._ Gallium nitride wafer slicing by a sub-nanosecond laser:

effect of pulse energy and laser shot spacing. _Appl. Phys. A_ 127, 648 (2021). Article ADS CAS Google Scholar * Bruel, M. Silicon on insulator material technology. _Electron. Lett._

31, 1201 (1995). Article ADS CAS Google Scholar * Bruel, M. Application of hydrogen ion beams to silicon on insulator material technology. _Nucl. Instr. And Meth. Phys. Res. B_ 108, 313

(1996) * Tauzin, A. _et al._ Transfers of 2-inch GaN films onto sapphire substrates using Smart Cut™ technology. _Electron. Lett._ 41, 668 (2005). Article ADS CAS Google Scholar *

Moutanabbir, O. & Gösele, U. Bulk GaN ion cleaving. _J. Electron. Mater._ 39, 482 (2010). Article ADS CAS Google Scholar * Iwinska, M. _et al._ HVPE-GaN growth on GaN-based advanced

substrates by Smart Cut™. _J. Cryst. Growth_ 456, 73 (2016). Article ADS CAS Google Scholar * F. Fukuyo, K. Fukumitsu, N. Uchiyama (2005) The stealth dicing technologies and their

applications. _Proc. 6thInt. Symp. on Laser Precision Microfabrication_ (2005). * Twyman, F. _Prism and lens making_ Vol. 318 (Hilger and Watts, 1952). Google Scholar * Nikolova, E. G. On

the Twyman effect and some of its applications. _J. Mater. Sci._ 20, 1 (1985). Article ADS CAS Google Scholar * Lee, K. J. _et al._ Bendable GaN high electron mobility transistors on

plastic substrates. _J. Appl. Phys._ 100, 124507 (2006). Article ADS Google Scholar * Shervin, S. _et al._ Strain-effect transistors: Theoretical study on the effects of external strain

on III-nitride high-electron-mobility transistors on flexible substrates. _Appl. Phys. Lett._ 107, 1904 (2015). Article Google Scholar * Wang, A., Zeng, L., Wang, W. & Calle, F.

Modification of strain and 2DEG density induced by wafer bending of AlGaN/GaN heterostructure: Influence of edges caused by processing. _AIP Adv._ 8, 035318 (2018). Article ADS Google

Scholar * Wang, W. _et al._ Modulation of the two-dimensional electron gas channel in flexible AlGaN/GaN high-electron-mobility transistors by mechanical bending. _Appl. Phys. Lett._ 116,

1201 (2020). Google Scholar Download references ACKNOWLEDGEMENTS Part of this research was conducted under contract of R&D for the expansion of radio wave resources (JPJ000254),

organized by the Ministry of Internal Affairs and Communications, Japan. AUTHOR INFORMATION AUTHORS AND AFFILIATIONS * Center for Integrated Research of Future Electronics (CIRFE), Institute

of Materials and Systems for Sustainability (IMaSS), Nagoya University, Aichi, 464-8601, Japan Atsushi Tanaka, Hirotaka Watanabe, Hadi Sena, Yuto Ando, Yoshio Honda, Yuji Ando & Hiroshi

Amano * National Institute for Materials Science, Tsukuba, 987-6543, Japan Atsushi Tanaka * Research & Development Department, Electron Tube Division, Hamamatsu Photonics K. K.,

Shizuoka, 438-0193, Japan Ryuji Sugiura, Daisuke Kawaguchi, Yotaro Wani & Yasunori Igasaki * Department of Electrical and Mechanical Engineering, Nagoya Institute of Technology, Aichi,

466-8555, Japan Akio Wakejima Authors * Atsushi Tanaka View author publications You can also search for this author inPubMed Google Scholar * Ryuji Sugiura View author publications You can

also search for this author inPubMed Google Scholar * Daisuke Kawaguchi View author publications You can also search for this author inPubMed Google Scholar * Yotaro Wani View author

publications You can also search for this author inPubMed Google Scholar * Hirotaka Watanabe View author publications You can also search for this author inPubMed Google Scholar * Hadi Sena

View author publications You can also search for this author inPubMed Google Scholar * Yuto Ando View author publications You can also search for this author inPubMed Google Scholar * Yoshio

Honda View author publications You can also search for this author inPubMed Google Scholar * Yasunori Igasaki View author publications You can also search for this author inPubMed Google

Scholar * Akio Wakejima View author publications You can also search for this author inPubMed Google Scholar * Yuji Ando View author publications You can also search for this author inPubMed

Google Scholar * Hiroshi Amano View author publications You can also search for this author inPubMed Google Scholar CONTRIBUTIONS Atsushi Tanaka wrote all parts of the manuscript. All

authors reviewed the manuscript. CORRESPONDING AUTHOR Correspondence to Atsushi Tanaka. ETHICS DECLARATIONS COMPETING INTERESTS The authors declare no competing interests. ADDITIONAL

INFORMATION PUBLISHER'S NOTE Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations. The original online version of this

Article was revised: The original version of this Article contained a repeated error where the symbol for micrometres “μm” was incorrectly given as millimetres “mm” in the Introduction,

Experiments, Results and discussion, Figure 2 legend and the Conclusion. RIGHTS AND PERMISSIONS OPEN ACCESS This article is licensed under a Creative Commons Attribution 4.0 International

License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source,

provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative

Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not

permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit

http://creativecommons.org/licenses/by/4.0/. Reprints and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Tanaka, A., Sugiura, R., Kawaguchi, D. _et al._ Laser slice thinning of GaN-on-GaN

high electron mobility transistors. _Sci Rep_ 12, 7363 (2022). https://doi.org/10.1038/s41598-022-10610-4 Download citation * Received: 04 January 2022 * Accepted: 11 April 2022 * Published:

05 May 2022 * DOI: https://doi.org/10.1038/s41598-022-10610-4 SHARE THIS ARTICLE Anyone you share the following link with will be able to read this content: Get shareable link Sorry, a

shareable link is not currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt content-sharing initiative